21.02.2024

Carbon concrete – prospects for the construction industry.

Carbon concrete may soon become as popular a building material as reinforced concrete.

In pursuit of environmental trends, companies are developing various technologies and materials that cause the least harm to the environment and affect human health.

Reinforced concrete, which is popular in construction today, is resource-intensive to produce and has a negative impact on the environment.

The international architectural firm HENN designed and built the experimental one-story building The Cube in Dresden.

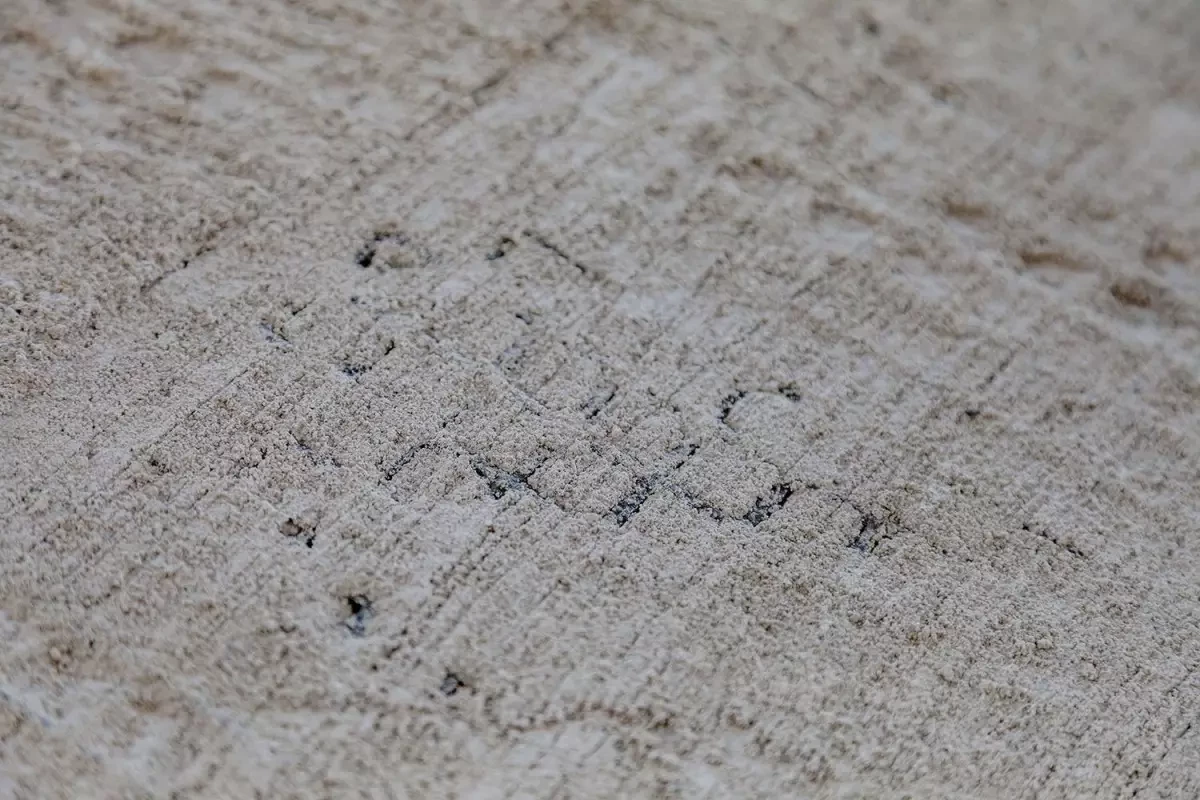

Carbon concrete technology consists of using a fine carbon fiber mesh instead of steel to give the structure additional strength. This makes it possible to create more flexible forms and reduce the number of joints.

Monolithic structures made of carbon concrete are stronger and more durable than reinforced concrete. Buildings made of this material will last twice as long as those made of reinforced concrete – a bridge made of carbon concrete will last 80 years without repair, while a bridge made of traditional material will “live” until repairs are needed for 40-50 years.

Another cool advantage of the new material is its small thickness with higher strength.

To protect the iron reinforcement from moisture, it is necessary to fill it with a large amount of concrete, and the monoliths turn out to be voluminous. Carbon fiber does not rust, so less concrete is needed.

At the same time, there is no need to doubt the strength of the fiber.

According to the head of the sales department of the Nanotechnology Center of Composites (NCC) Evgeny Rafailov: “Carbon fiber is 5 times stronger than reinforcing steel… The use of an external reinforcement system based on carbon fiber allows us to increase the load-bearing capacity of structures, but without increasing the load – which is extremely important.”

The production of innovative concrete reduces carbon emissions and results in significant savings in the use of water and sand.

And the most interesting indicator for creative architects is that carbon concrete can be used to experiment with shaping.

When comparing construction costs using reinforced or carbon concrete, you should not focus only on the fact that the latter is several times more expensive than traditional material. It is also necessary to take into account that significant savings arise from the lack of need for heavy equipment and welding.

In addition, carbon concrete allows work to be carried out in confined spaces.

And a completely unique property - carbon fiber is conductive, and if you pass a light current through it, you can generate heat. This is the property used in the project The Cube. The concrete walls of the building are equipped with insulating pads, heating elements and various sensor surfaces.

The Cube is a full-fledged educational building of the Technical University of Dresden. The building with a total area of 220 square meters houses a classroom, a laboratory, a seminar room, and a kitchen.

Thanks to the use of carbon concrete in a small building, it was possible to gain more useful area due to the thickness of the walls. The innovative material allowed to create a flexible design of the building - to bend the walls and ceilings.

The building’s appearance is completed by large volumes of panoramic glazing and a diagonal skylight on the roof.

The use of carbon concrete in design projects gives modern architects the opportunity to show themselves as advanced designers, as specialists who keep up with the times. This is a good motivation and the key to your success.

The article was useful to you?

4

166

0